Cement tiles

Craftsmanship, history, and design with character

Cement tiles are more than just flooring. They are a piece of architectural history, a mineral-bound building material with soul and expressiveness. Each cement tile is handcrafted from marble powder, rock flour, color pigments, and high-quality cement. Unlike ceramic or porcelain stoneware, they are not fired, but manufactured using a pressing process and then air-dried. This mineral binding gives the surface its velvety feel, its special depth, and its characteristic patina, which only becomes more beautiful with age.

VIA manufactures cement tiles based on historical models – authentic, ecological, and reversible. Each tile is pressed individually, compacted with marble powder and marble dust, and colored with natural pigments. The result is a mineral-bound surface that remains breathable and retains its warm, powdery color.

Origin and tradition

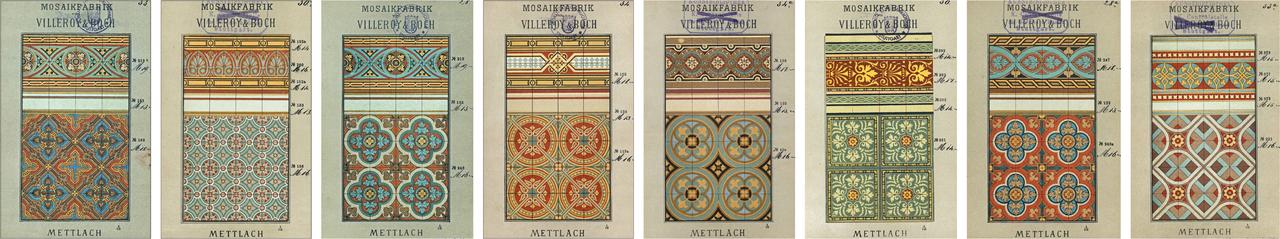

Cement tiles have their roots in the Mediterranean region. In Barcelona, France, and Italy, they continue to shape the character of residential buildings, cafés, and entrance areas to this day. During the Catalan Modernism period, in buildings and in the designs of Antoni Gaudí, they became a symbol of Mediterranean interior design. The influence of Art Nouveau and Art Deco can be seen in many historical patterns – from floral ornaments to geometric structures. During the Wilhelminian period and later in the architecture of Berlin and Cologne, cement tiles were also considered a high-quality building material with artistic appeal.

Villeroy & Boch, Mettlach, and numerous manufacturers in southern Germany and France shaped the industrial production of ceramic and cement mosaic tiles from the 19th century onwards. While ceramic tiles were glazed and fired, cement tiles, as mineral-bound slabs, always remained a handcrafted product with an unmistakable feel and depth of color.

Manufacturing and materials

The heart of every cement tile is its structure. The top layer—known as the facing layer—consists of a mixture of marble powder, marble dust, rock powder, cement, and color pigments. This is poured into molds, then bonded to the gray cement base and compacted using a pressing process. Hydraulic setting creates a solid, homogeneous composite, without any firing process or plastic additives. This process fundamentally distinguishes genuine cement tiles from imitation cement tiles made from industrially manufactured porcelain stoneware or concrete-look slabs.

Each tile is made entirely by hand. Color variations and fine irregularities are part of the character of the material. This naturalness makes every surface lively and unique. It is reminiscent of terrazzo tiles and cast stone, but remains finer and more sensual in appearance.

Design and pattern

The design possibilities are virtually unlimited. Cement tiles are traditionally manufactured as patterned tiles, mosaics, or motif tiles. Historical designs from the Wilhelminian era, Art Nouveau, or Art Deco can be realized just as easily as modern, clean compositions. Geometric shapes, color gradients, and hexagonal tiles create rooms with character and depth. Every combination – whether classic Mediterranean, French elegance, or Scandinavian minimalism – tells its own story.

The VIA sample tiles demonstrate the diversity of these design options. Combinations of plain and patterned tiles, borders, and center motifs open up creative freedom for interior design and individual room concepts. Whether for kitchen floors, hallways in old buildings, bathrooms, or living areas, cement tiles combine craftsmanship with creative freedom.

Installation and technology

Laying the tiles requires precision and knowledge of the material. Cement tiles are laid using VIA tile adhesivein a process known as buttering-floating to ensure full-surface adhesion. After setting, grouting is carried out using a fine grouting material (consisting of a mixture of trass cement and quartz sand) and the appropriate grouting board. A narrow joint width – maximum of 2 mm – emphasizes the calm overall appearance of the surface.

Cement tiles are suitable for indoor use as well as for protected outdoor areas. They work excellently in combination with underfloor heating, as they store heat evenly and release it slowly. Their natural composition makes them diffusion-open, which regulates humidity and improves the indoor climate.

Surface treatment and care

After laying and completely drying the covering, the surface of the cement tiles must be treated. Only then will it be protected against moisture, dirt, and chemical exposure.

There are three systems to choose from, depending on the desired look, use, and maintenance intensity:

Surface Treatment Comparison

VIA Tile Oil

natural color enrichment

- Protection principle

- deep impregnation into the capillary structure

- Appearance

- warm color enhancement, matte

- Haptic

- velvety, open pore

- Application

- work in thin and evenly, remove excess

- Use

- living spaces, kitchens, heritage buildings

- Maintenance

- low to medium, refreshable without sanding

- Chemical exposure

- clean with pH neutral products, avoid acidic agents

VIA Mineral Impregnation

mineral base protection

- Protection principle

- silicification through water glass

- Appearance

- very natural matte, low color enhancement

- Haptic

- mineral, breathable

- Application

- apply with a wiper in cross strokes, very thin liquid

- Use

- hallways, kitchens, entrance areas

- Maintenance

- low, easy to reapply

- Chemical exposure

- clean with pH neutral products, avoid acidic agents

VIA Sealer

maximum surface protection

- Protection principle

- film forming, separates surface from external influences

- Appearance

- satin matte, very even

- Haptic

- smoother, closed protective layer

- Application

- apply evenly, film forming

- Use

- gastronomy, shops, bathrooms, high traffic areas

- Maintenance

- very low, easy cleaning

- Chemical exposure

- suitable for acidic cleaners

Allow the surface to dry completely before applying any treatment.

Applications and rooms

Cement tiles are effective in almost any context. In old buildings, they emphasize historical structures, while in modern architecture, they create artisanal contrasts. They are suitable as flooring in kitchens, bathrooms, hallways, and living rooms, on kitchen surfaces, or in representative entrance areas. They also create harmonious transitions when combined with wood floors, natural stone, or terrazzo tiles. Their versatility makes them ideal for interior spaces with character—from private living spaces to public buildings, from Berlin to Cologne to France and Barcelona.

Ordering and service

VIA offers cement tiles in numerous formats, colors, and patterns. Sample tiles can be ordered to experience the original surface and color effect. Many designs are available from stock, while others are custom-made. Delivery times depend on the motif and quantity. Prices, samples, and available series are provided upon request.

VIA operates a showroom on the Middle Rhine, where the entire collection is on display – from classic ornaments to modern, minimalist surfaces. Advice, ordering, and shipping are handled directly from the factory, throughout Europe.

Quality and sustainability

Cement tiles are completely mineral-based, free from plastics, and fully recyclable. As a pure building material made from marble powder, rock flour, and pigments, it contributes to a healthy indoor climate. Compared to industrial cement tile imitations or ceramic porcelain stoneware tiles, genuine cement tiles have an inimitable depth and authenticity. They last for generations, and their surface tells stories.

Every VIA cement tile is a piece of craftsmanship, culture, and design—ecological, robust, and beautiful.